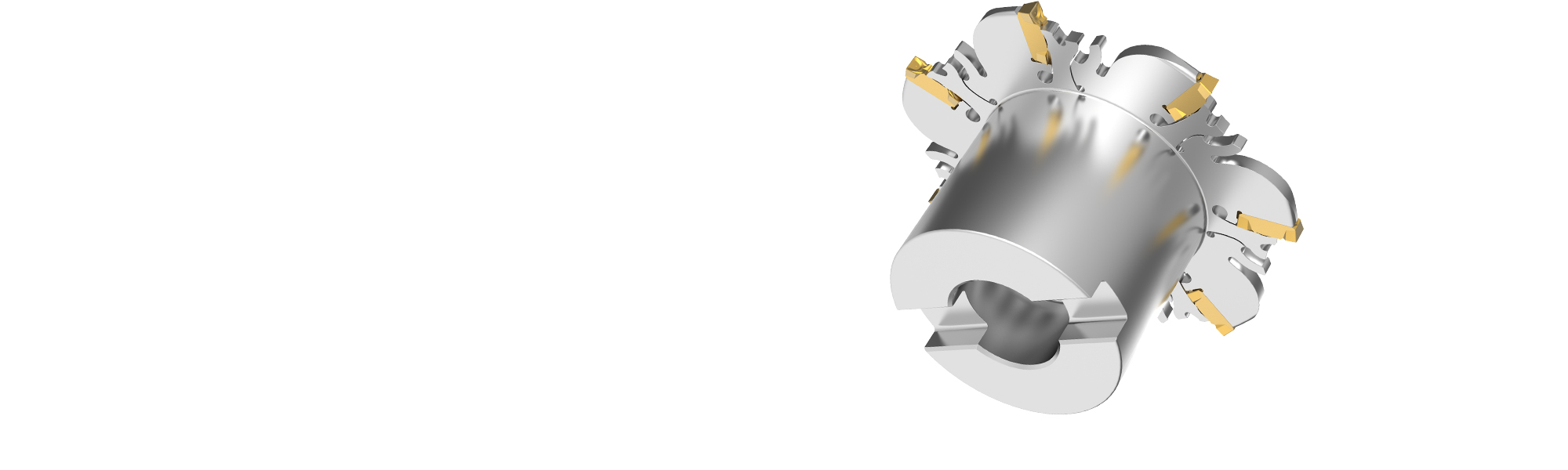

The Double-V Design of the insert and the insert pocket securely holds the insert in place and minimizes radial runout.

As a result, these stable cutting conditions lead to high slot width accuracy and high repeatability.

A unique self-clamping mechanism ensures easy insert exchange.

From light to heavy machining, the positive SGP chipbreaker geometry ensures smooth cutting action, and efficient chip evacuation.