Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

Downloaded file will be available after import in the {{cadTool}} tool library.

| Poradnik doboru płytek | ||||||

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| – | (Lekka geometria) | – | (Zgrubna geometria) | |||

| – | odporność na zużycie |  | ciągliwość | |||

| – | Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek |

| P1-P2 | .E..GE | KCPM40 | .S..GE | KCPM40 | .S..GEM | KCPM40 |

| P3-P4 | .E..GE | KCPM40 | .S..GE | KCPK30 | .S..GEM | KCPK30 |

| P5-P5 | .E..GE | KC725M | .S..GE | KC725M | .S..GEM | KCPK30 |

| M1-M2 | .E..GE | KCSM40 | .S..GE | KCSM40 | .S..GEM | KCPM40 |

| M3 | .E..GE | KCPM40 | .S..GE | KCPM40 | .S..GEM | KCPM40 |

| K1-K2 | .S..GE | KCK20B | .S..GE | KCK15 | .S..GEM | KCK20B |

| K3 | .S..GE | KCK20B | .S..GE | KCK15 | .S..GEM | KCK20B |

| N1-N2 | .E..GEJ | KC422M | .E..GEJ | KC422M | .E..GEJ | KC422M |

| N3 | .E..GEJ | KC422M | .E..GEJ | KC422M | .E..GEJ | KC422M |

| S1-S2 | .E..GE | KC725M | .S..GE | KC725M | .S..GE | KC725M |

| S3 | .E..GE | KCSM40 | .S..GE | KCSM40 | .S..GE | KCSM40 |

| S4 | .E..GE | KCSM40 | .S..GE | KCSM40 | .S..GE | KCSM40 |

| H1 | – | – | – | – | – | – |

| Zalecane wyjściowe wartości posuwu [cal/ostrze] | |||||||||||||||

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| .E..GEJ | 0,12 | 0,47 | 0,84 | 0,08 | 0,34 | 0,60 | 0,06 | 0,26 | 0,45 | 0,06 | 0,22 | 0,39 | 0,05 | 0,20 | 0,36 |

| .E..GE | 0,23 | 0,54 | 0,93 | 0,17 | 0,39 | 0,67 | 0,13 | 0,29 | 0,50 | 0,11 | 0,25 | 0,44 | 0,10 | 0,23 | 0,40 |

| .S..GE | 0,23 | 0,59 | 0,95 | 0,17 | 0,43 | 0,68 | 0,13 | 0,32 | 0,51 | 0,11 | 0,28 | 0,44 | 0,10 | 0,25 | 0,41 |

| .S..GER | 0,23 | 0,59 | 0,95 | 0,17 | 0,43 | 0,68 | 0,13 | 0,32 | 0,51 | 0,11 | 0,28 | 0,44 | 0,10 | 0,25 | 0,41 |

| .S..GEM | 0,23 | 0,59 | 0,95 | 0,17 | 0,43 | 0,68 | 0,13 | 0,32 | 0,51 | 0,11 | 0,28 | 0,44 | 0,10 | 0,25 | 0,41 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | |||||||||||||||

| Mill 4-15™ • Recommended Starting Feeds [IPT] | |||||||||||||||

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| .E..GEJ | 0.005 | 0.019 | 0.034 | 0.003 | 0.014 | 0.024 | 0.003 | 0.010 | 0.018 | 0.002 | 0.009 | 0.016 | 0.002 | 0.008 | 0.014 |

| .E..GE | 0.009 | 0.020 | 0.035 | 0.007 | 0.015 | 0.025 | 0.005 | 0.011 | 0.019 | 0.004 | 0.009 | 0.016 | 0.004 | 0.009 | 0.015 |

| .S..GE | 0.009 | 0.023 | 0.037 | 0.007 | 0.017 | 0.027 | 0.005 | 0.013 | 0.020 | 0.004 | 0.011 | 0.017 | 0.004 | 0.010 | 0.016 |

| .S..GER | 0.009 | 0.023 | 0.037 | 0.007 | 0.017 | 0.027 | 0.005 | 0.013 | 0.020 | 0.004 | 0.011 | 0.017 | 0.004 | 0.010 | 0.016 |

| .S..GEM | 0.009 | 0.023 | 0.037 | 0.007 | 0.017 | 0.027 | 0.005 | 0.013 | 0.020 | 0.004 | 0.011 | 0.017 | 0.004 | 0.010 | 0.016 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | |||||||||||||||

| Mill 4-15™ • Recommended Starting Speed [m/min] | |||||||||||||||||||||||||||||||

| Gatunek | KCPM20 | KC422M | KC522M | KC725M | KCK15 | KCPK30 | KCK20B | KCPM40 | KCSM30 | KCSM40 | |||||||||||||||||||||

| Grubość wióra hex mm | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | |||||||||||

| Grupa materiałowa | Maks. | Początek | Min. | Maks. | Początek | Min. | Maks. | Początek | Min. | Maks. | Początek | Min. | Maks. | Początek | Min. | Maks. | Początek | Min. | Maks. | Początek | Min. | Maks. | Początek | Min. | Maks. | Początek | Min. | Maks. | Początek | Min. | |

| P | 1 | 550 | 485 | 450 | – | – | – | 330 | 285 | 270 | 260 | 230 | 215 | – | – | – | 455 | 395 | 370 | – | – | – | 295 | 260 | 245 | 370 | 320 | 300 | 350 | 320 | 300 |

| 2 | 340 | 310 | 275 | – | – | – | 275 | 240 | 200 | 220 | 190 | 160 | – | – | – | 280 | 255 | 230 | – | – | – | 250 | 215 | 180 | 305 | 270 | 220 | 300 | 270 | 220 | |

| 3 | 310 | 275 | 255 | – | – | – | 255 | 215 | 175 | 200 | 170 | 140 | – | – | – | 255 | 230 | 205 | – | – | – | 230 | 195 | 160 | 285 | 240 | 195 | 280 | 240 | 195 | |

| 4 | 230 | 215 | 190 | – | – | – | 225 | 185 | 150 | 180 | 150 | 120 | – | – | – | 225 | 185 | 160 | – | – | – | 205 | 170 | 135 | 250 | 205 | 165 | 240 | 205 | 165 | |

| 5 | 275 | 250 | 230 | – | – | – | 185 | 170 | 150 | 150 | 135 | 120 | – | – | – | 190 | 170 | 150 | – | – | – | 170 | 155 | 135 | 205 | 190 | 165 | 200 | 180 | 160 | |

| 6 | 190 | 170 | 145 | – | – | – | 165 | 125 | 100 | 130 | 100 | 80 | – | – | – | 160 | 135 | 110 | – | – | – | 150 | 115 | 90 | 185 | 140 | 110 | 180 | 140 | 100 | |

| M | 1 | 225 | 200 | 175 | – | – | – | 205 | 180 | 165 | 170 | 150 | 135 | – | – | – | 205 | 185 | 155 | – | – | – | 195 | 170 | 155 | 225 | 180 | 170 | 260 | 210 | 185 |

| 2 | 205 | 175 | 160 | – | – | – | 185 | 160 | 130 | 155 | 130 | 110 | – | – | – | 185 | 160 | 140 | – | – | – | 175 | 150 | 125 | 205 | 160 | 135 | 235 | 180 | 145 | |

| 3 | 160 | 145 | 125 | – | – | – | 140 | 120 | 95 | 115 | 100 | 80 | – | – | – | 145 | 130 | 115 | – | – | – | 130 | 115 | 90 | 155 | 125 | 95 | 175 | 145 | 110 | |

| K | 1 | 360 | 325 | 295 | – | – | – | 230 | 205 | 185 | – | – | – | 420 | 385 | 340 | 295 | 265 | 240 | 360 | 290 | 245 | – | – | – | – | – | – | – | – | – |

| 2 | 285 | 255 | 235 | – | – | – | 180 | 160 | 150 | – | – | – | 335 | 295 | 275 | 235 | 210 | 190 | 280 | 230 | 195 | – | – | – | – | – | – | – | – | – | |

| 3 | 240 | 215 | 200 | – | – | – | 150 | 135 | 120 | – | – | – | 280 | 250 | 230 | 195 | 175 | 160 | 210 | 175 | 140 | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | 1075 | 945 | 875 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 | 50 | 40 | 25 |

| 2 | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 | 55 | 40 | 25 | |

| 3 | – | – | – | – | – | – | 50 | 40 | 25 | 45 | 35 | 25 | – | – | – | – | – | – | – | – | – | 50 | 40 | 30 | 55 | 45 | 30 | 65 | 45 | 30 | |

| 4 | – | – | – | – | – | – | 50 | 45 | 35 | 50 | 45 | 30 | – | – | – | 50 | 45 | 35 | – | – | – | 55 | 50 | 35 | 60 | 55 | 40 | 75 | 60 | 40 | |

| H | 1 | 140 | 115 | 95 | – | – | – | 120 | 90 | 70 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 135 | 100 | 75 | – | – | – |

| UWAGA: PIERWSZY wybór dla wyjściowych wartości prędkości skrawania zaznaczono pogrubioną czcionką. Prędkość skrawania należy zmniejszać w miarę zwiększania średniej grubości wióra. | |||||||||||||||||||||||||||||||

| Mill 4-15™ • Recommended Starting Speed [SFM] | |||||||||||||||||||||||||||||||

| Gatunek | KCPM20 | KC422M | KC522M | KC725M | KCK15 | KCPK30 | KCK20B | KCPM40 | KCSM30 | KCSM40 | |||||||||||||||||||||

| Chip Thickness hex Inch | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | |||||||||||

| Grupa materiałowa | Maks. | Początek | Min. | Maks. | Początek | Min. | Maks. | Początek | Min. | Maks. | Początek | Min. | Maks. | Początek | Min. | Maks. | Początek | Min. | Maks. | Początek | Min. | Maks. | Początek | Min. | Maks. | Początek | Min. | Maks. | Początek | Min. | |

| P | 1 | 1805 | 1590 | 1475 | – | – | – | 1085 | 935 | 885 | 855 | 755 | 705 | – | – | – | 1495 | 1295 | 1215 | – | – | – | 970 | 855 | 805 | 1215 | 1050 | 985 | 1150 | 1050 | 985 |

| 2 | 1115 | 1015 | 900 | – | – | – | 900 | 785 | 655 | 720 | 625 | 525 | – | – | – | 920 | 835 | 755 | – | – | – | 820 | 705 | 590 | 1000 | 885 | 720 | 985 | 885 | 720 | |

| 3 | 1015 | 900 | 835 | – | – | – | 835 | 705 | 575 | 655 | 560 | 460 | – | – | – | 835 | 755 | 675 | – | – | – | 755 | 640 | 525 | 935 | 785 | 640 | 920 | 785 | 640 | |

| 4 | 755 | 705 | 625 | – | – | – | 740 | 605 | 490 | 590 | 490 | 395 | – | – | – | 740 | 605 | 525 | – | – | – | 675 | 560 | 445 | 820 | 675 | 540 | 785 | 675 | 540 | |

| 5 | 900 | 820 | 755 | – | – | – | 605 | 560 | 490 | 490 | 445 | 395 | – | – | – | 625 | 560 | 490 | – | – | – | 560 | 510 | 445 | 675 | 625 | 540 | 655 | 590 | 525 | |

| 6 | 625 | 560 | 475 | – | – | – | 540 | 410 | 330 | 425 | 330 | 260 | – | – | – | 525 | 445 | 360 | – | – | – | 490 | 375 | 295 | 605 | 460 | 360 | 590 | 460 | 330 | |

| M | 1 | 740 | 655 | 575 | – | – | – | 675 | 590 | 540 | 560 | 490 | 445 | – | – | – | 675 | 605 | 510 | – | – | – | 640 | 560 | 510 | 740 | 590 | 560 | 855 | 690 | 605 |

| 2 | 670 | 575 | 525 | – | – | – | 605 | 525 | 425 | 510 | 425 | 360 | – | – | – | 605 | 525 | 460 | – | – | – | 575 | 490 | 410 | 675 | 525 | 445 | 770 | 590 | 475 | |

| 3 | 525 | 475 | 410 | – | – | – | 460 | 395 | 310 | 375 | 330 | 260 | – | – | – | 475 | 425 | 375 | – | – | – | 425 | 375 | 295 | 510 | 410 | 310 | 575 | 475 | 360 | |

| K | 1 | 1180 | 1065 | 970 | – | – | – | 755 | 675 | 605 | – | – | – | 1380 | 1265 | 1115 | 970 | 870 | 785 | 1180 | 950 | 805 | – | – | – | – | – | – | – | – | – |

| 2 | 935 | 835 | 770 | – | – | – | 590 | 525 | 490 | – | – | – | 1100 | 970 | 900 | 770 | 690 | 625 | 920 | 755 | 640 | – | – | – | – | – | – | – | – | – | |

| 3 | 785 | 705 | 655 | – | – | – | 490 | 445 | 395 | – | – | – | 920 | 820 | 755 | 640 | 575 | 525 | 690 | 575 | 460 | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | 2100 | 1870 | 1725 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | 1905 | 1755 | 1610 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | 1905 | 1755 | 1610 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 130 | 115 | 80 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 150 | 130 | 100 | 165 | 130 | 80 |

| 2 | – | – | – | – | – | – | 130 | 115 | 80 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 150 | 130 | 100 | 180 | 130 | 80 | |

| 3 | – | – | – | – | – | – | 165 | 130 | 80 | 150 | 115 | 80 | – | – | – | – | – | – | – | – | – | 165 | 130 | 100 | 180 | 150 | 100 | 215 | 150 | 100 | |

| 4 | – | – | – | – | – | – | 165 | 150 | 115 | 165 | 150 | 100 | – | – | – | 165 | 150 | 115 | – | – | – | 180 | 165 | 115 | 195 | 180 | 130 | 245 | 195 | 130 | |

| H | 1 | 460 | 375 | 310 | – | – | – | 395 | 295 | 230 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 445 | 330 | 245 | – | – | – |

| As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | |||||||||||||||||||||||||||||||

| ||||

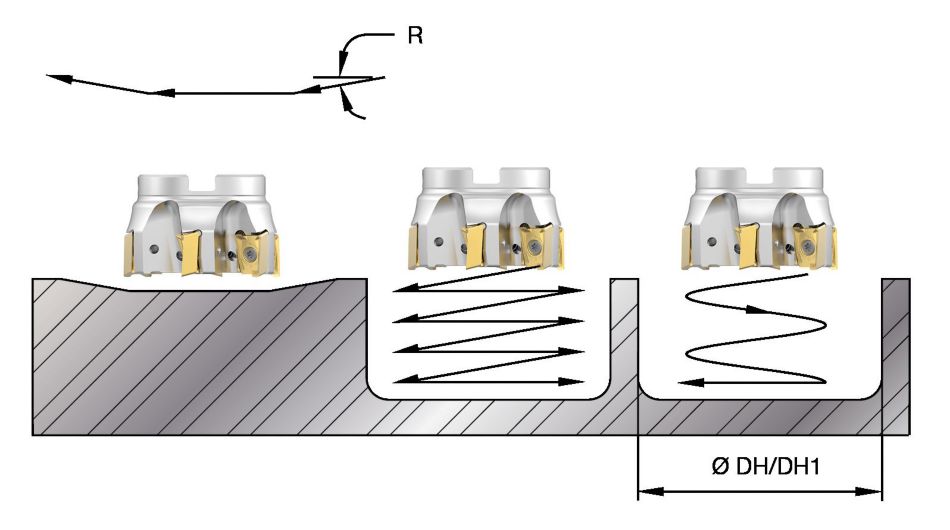

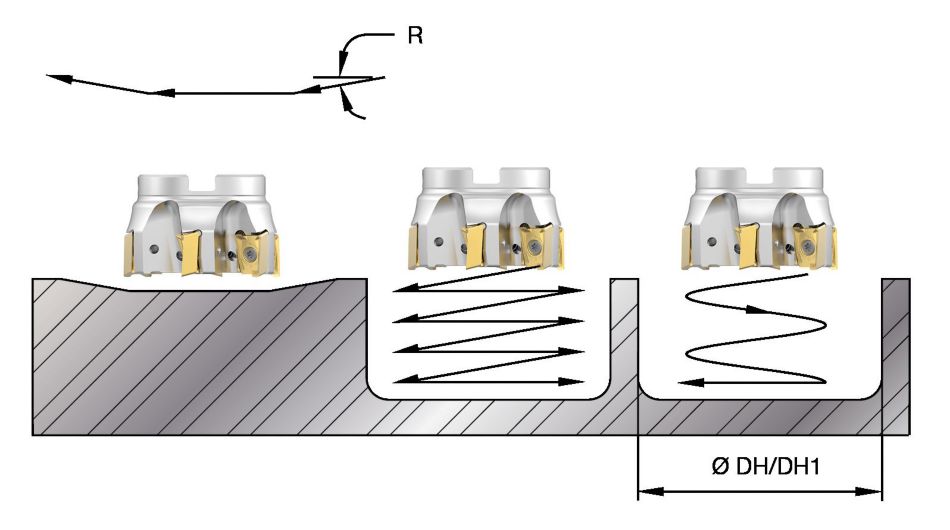

| Mill 4-15™ • Ramping Appplication Data • SGE-R Geometry Insert [mm] | ||||

| średnica frezu | maks. kąt wcinania [R] | DH min [mm] - (min hole diameter) | DH min (min. średnica otworu) | DHI min (min. średnica otworu przy dnie płaskim) |

| 25 | 2,63° | 44,77 | 50 | 47,16 |

| 32 | 2,38° | 58,64 | 64 | 60,81 |

| 35 | 2,12° | 64,61 | 70 | 66,75 |

| 40 | 1,80° | 74,57 | 80 | 76,82 |

| 50 | 1,38° | 94,53 | 100 | 96,72 |

| 63 | 1,06° | 120,52 | 126 | 122,72 |

| 80 | 0,82° | 154,52 | 160 | 156,73 |

| 100 | 0,64° | 194,52 | 200 | 196,73 |

| 125 | 0,51° | 244,51 | 250 | 246,73 |

| 160 | 0,51° | 314,51 | 320 | 316,74 |

| ||||

| Mill 4-15™ • Ramping Appplication Data • SGE-R Geometry Insert [Inch] | ||||

| średnica frezu | maks. kąt wcinania [R] | DH min [Inch] - (min hole diameter) | DH min (min. średnica otworu) | DHI min (min. średnica otworu przy dnie płaskim) |

| 1" | 2.60° | 1.794" | 2" | 1.888" |

| 1.25" | 2.39° | 2.289" | 2.5" | 2.374" |

| 1.5" | 1.91° | 2.786" | 3" | 2.874" |

| 2" | 1.36° | 3.784" | 4" | 3.871" |

| 2.5" | 1.05° | 4.784" | 5" | 4.871" |

| 3" | 0.86° | 5.784" | 6" | 5.781" |

| 4" | 0.63° | 7.784" | 8" | 7.871" |

| 5" | 0.50° | 9.784" | 10" | 9.871" |

| 6" | 0.41° | 11.784" | 12" | 11.872" |

Oznaczenie katalogowe ISO

Oznaczenie katalogowe ANSI

to find similar products.Please select a file to download

Models

Product data

I have read and accepted the Terms & Conditions of use

Can’t find the file type you’re looking for?

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

Minimum quantity should be

| SAP Material Number | Oznaczenie katalogowe ISO | Gatunek |

|---|

You are about to leave the Solution building process.

Are you sure you want to leave?