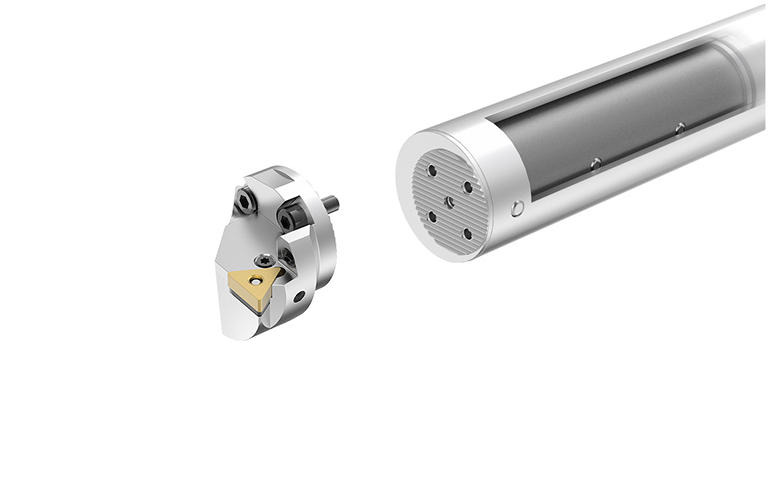

세레이션 인터페이스가 있는 모듈러 보링 바

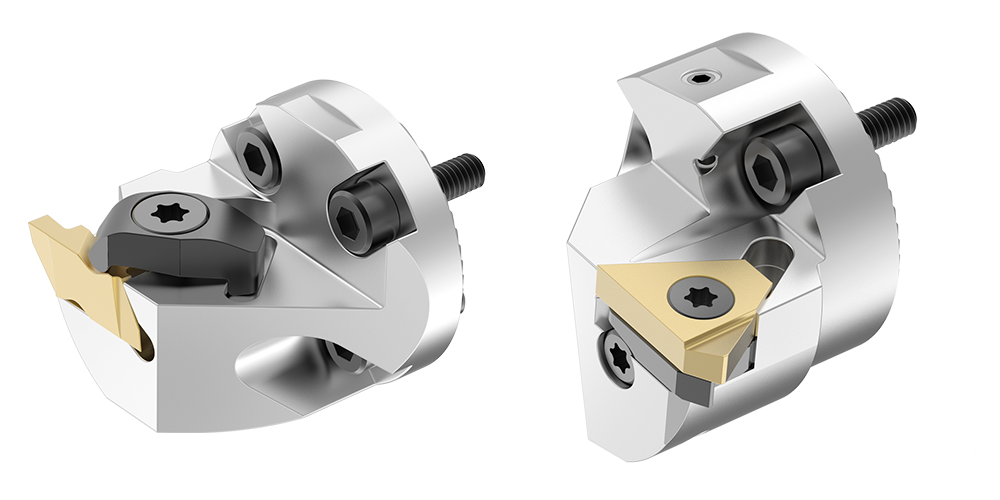

이러한 보링 바는 세레이션 디자인을 통해 바에 연결하는 새로운 볼트 온 헤드 포트폴리오를 활용합니다.

- 짧은 디자인의 볼트 온 헤드는 경량으로, 높은 안정성과 높은 반복 체결 정도를 제공합니다.

- 세레이션 설계 인터페이스는 더 높은 체결 강도를 제공하여 인서트 위치 지정의 정확성을 높입니다.

- 무진동 보링 바는 최대 10xD까지 연장된 오버행에서 보링할 때 높은 안정성과 강성을 제공합니다.

- 무진동 보링 바는 수동 조정 없이(가능하지 않음) 구입 즉시 작동하도록 설계된 플러그앤플레이 솔루션입니다. 내부 댐핑 패키지는 바의 강성을 높이고 채터를 줄여 안정적인 프로세스를 제공하도록 설계되었습니다.